Coating

Shahriar Turbine Components Company takes advantage of a wide range of coating equipment for application of different types of coatings on components.

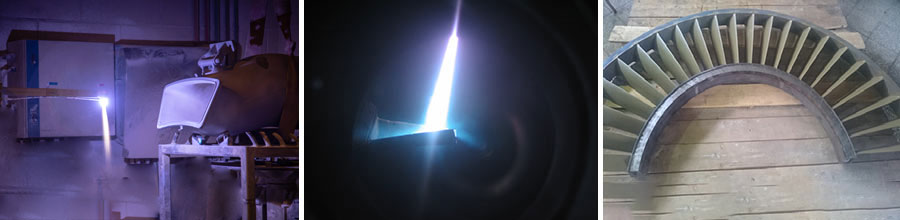

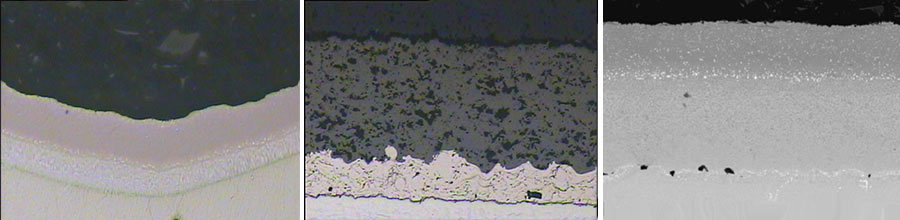

- Low Pressure Plasma Spray (LPPS) for application of high quality MCrAlY coatings.

- High Velocity Oxygen Fuel (HVOF) for application of high quality MCrAlY and hardface coatings.

- Air Plasma Spray (APS) for application of TBC and hardface coatings.

- CNC controlled ceramic peening machine.

The company is supplied with gas controlled furnaces and know how and equipment for application of Aluminide and Chromide diffusion coatings. Ability of application of aluminide coating on internal cooling passages is another critical ability of company.

Shahriar Turbine Components Company has a full furnished separate workshop for application of coatings on compressor components. It is also possible to carry out all coating procedure on these parts in assembled condition to save time for clients.